Thermal Bridging Analysis

Incremental changes to Part L means that meeting the fabric efficiency standards, as well as London Plan policy standards, requires careful attention to every detail of the design and construction process. So we like to get involved as early as possible, to make sure that every opportunity for maximising the energy efficiency of a building is taken.

A particular issue is that assessing the losses that result from thermal bridging often relies on backstop assumptions, especially in the case of medium and high-rise buildings where standardised published details aren’t applicable. However, backstops are penalised in energy assessment methodology, with further penalties proposed in future updates to Part L. Our Thermal Bridging Analysis removes the need for backstops and represents the most cost-effective alternative to expensive fabric uplift measures and renewable energy-generation systems.

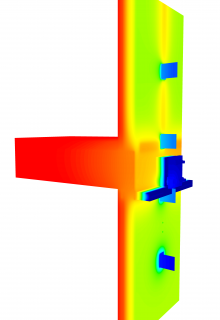

The analysis is appropriate for almost all medium-to-high-rise construction projects, and it makes sure that detailed structural elements that often penetrate the insulation envelope of a building are carefully specified. Our use of 3D models allows us to quickly substitute a variety of component parts that make up construction details, like balcony structure supports, meaning that products can be compared for specific construction. This means you can be as informed as possible when you choose your materials, understanding the thermal performance of a product before you commit to buying anything.